September is National Food Safety Education Month, which is a topic that we at MPSC focus on every day through our Rinse & Chill® technology. Enhancing meat quality and safety was part of MPSC’s founding vision, and we now have a track record of over 25 years of Rinse and Chill® successfully leading to safer meat products, longer shelf life, and enhanced quality for our customers. To highlight the importance of food safety and cleanliness at the meat plant level, we spotlight the story of MPSC and one of our Australian customers, which we refer to internally as “Plant X”.

MPSC has operated in Australia and New Zealand for over 20 years, receiving approval from the Australian and New Zealand Food Authority (ANZFA) in 2003 to bring our Rinse & Chill® technology to the region. In 2019, we began working with Plant X, a significant Australian lamb and sheep producer that handles up to 5,000 head per day. For several years, our partnership went along smoothly without any incidents, and in 2025, Plant X undertook a chilled lamb program to begin selling chilled lamb into the Domestic Supermarket trade with the ultimate goal to be exporting lamb to supermarkets in the United States. Australia exports roughly 75% of its meat production, and with many Australian retailers requiring a 45-day chilled shelf life and exported chilled product requiring 90 days, optimal meat hygiene is critical for global competitiveness in the North American and European markets.

In June 2025, MPSC was informed by Plant X’s distributor that meat from the plant was spoiling and not meeting the shelf-life requirements of Australian Domestic retailers. The distributor suggested the spoilage was linked to Rinse & Chill®, and Managing Director for MPSC Australia, Mick Bird, was quick to formulate a plan, saying, “Our success is intrinsically linked to our customers’ success. We’ll take this seriously and take accountability.”

Shelf life issues invariably arise from some combination of suboptimal cold chain management, poor hygiene, or contamination. This led the MPSC team to suspect there had to be issues with foreign material on the animals. Confident in their technology, Mick and team presented a collaborative plan with Plant X to investigate the problem together and increase the existing shelf life of 14-20 days up to 90 days. The decision was made in partnership with Plant X to persist with Rinse & Chill® in Plant X for three months and implement a rigorous and comprehensive “12-week Shelf-Life Project” to determine the cause of the spoilage and identify solutions, taking into account a holistic approach to assess all contributing factors.

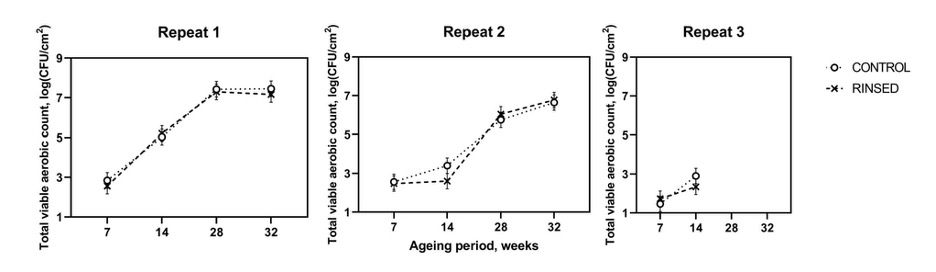

MPSC senior leadership, together with its key independent scientific consultant, initiated the project with a full plant audit to assess hygiene practices, a key step in order to determine the cause of the spoilage and make improvements. Early findings revealed there were significant areas of concern in plant hygiene and cleanliness. Over the 12 weeks, MPSC worked with a meat scientist to test samples of Rinse & Chill® lamb and a control sample of unrinsed products. These carcasses were taken for independent analysis by the New South Wales Department of Primary Industries (NSW Department of Primary Industries) to monitor the bacteria levels at 0, 4, 8, and 12 weeks.

During this period, MPSC issued a 54-page report with many recommendations for Plant X to improve hygiene and other processes, with the goal of taking the existing 14-20 day shelf life up to 90 days. The plant was cleaned to hospital-grade level, greater attention was paid to packaging quality control, and a hard chill program was implemented to get the meat temperature below zero degrees Celsius, which reduces and slows TVC growth and extends shelf life. After making these changes within the 12 weeks, Plant X achieved a 90-day chilled shelf life using Rinse & Chill®, a substantial increase that was critical for the Australian Domestic retailers and for exporting chilled products overseas. Independent analysis from the DPI confirmed that Rinse & Chill® technology was not causing the spoilage, and rather, the issue was caused by bacteria related to plant cleanliness. MPSC has received no further complaints from Plant X, and the distributor apologized and thanked our team for the support.

Mick Bird summarized MPSC’s role well, saying, “Our team has a great deal of experience and knowledge to share. As good as our technology is, it won’t absolve problems with hygiene and cold chain management. We can’t perform miracles, but we are happy to support our customers and use our expertise to improve their outcomes.” Rinse & Chill® technology delivers many benefits to our customers, but even more than that, MPSC offers seasoned experience to help our clients solve challenges from the technical to HR and regulatory. Our team steps up when needed because our interests are so closely aligned with those of our clients.